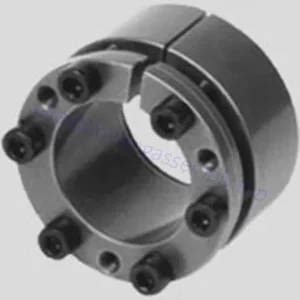

Locking Assembly

The locking assembly is a friction locking hub connection manufactured to the highest quality standards. They are suitable for the precise fastening of all types of hubs, such as gears, running and sprockets, levers, cam discs, belts and brake discs, sliding gears, couplings or flanges, shafts and axles. In contrast to external clamping connections such as shrink discs, the locking assembly is mounted between the shaft and hub.

We will reply to your email within 24 hours.

Features of Locking Assemblies

Torque Transmission

Locking assemblies are designed to transmit torque efficiently and reliably between rotating components. They provide a strong and rigid connection, ensuring the transfer of power without slippage or loss.

Backlash-Free Operation

Locking assemblies minimize or eliminate backlash, which refers to the undesired movement or play between interconnected components. This feature helps maintain precise positioning and accurate torque transmission.

Precise Alignment

Locking assemblies aid in maintaining precise alignment between the shaft and the connected component. This feature minimizes vibration, reduces wear and tear, and enhances the overall efficiency and lifespan of the system.

Easy Installation and Removal

Many locking assemblies are designed for straightforward installation and removal, allowing for convenient assembly, disassembly, and maintenance. They often involve simple and user-friendly mounting procedures, reducing downtime and labor costs.

Resistance to Environmental Factors

Locking assemblies are often designed to withstand challenging environmental conditions, such as temperature variations, moisture, dirt, and corrosion. They may be constructed from materials with high strength and corrosion resistance to ensure reliable performance in demanding environments.

Compatibility

Locking assemblies can be used with different types of rotating components, including shafts, hubs, flanges, pulleys, sprockets, and more. They offer compatibility with standard dimensions and interfaces, making them compatible with a variety of existing systems and components.

How Locking Assemblies Operate

The locking mechanism is placed between the hub and the shaft. They are available in a range of styles, such as three, two, or four rings. They comprise an inner ring and an outer ring, a top band, a lower ring, and an external ring; or an inside ring, and an outer ring as well as a rear ring and an outer ring.

Lock the screw using a torque wrench, and then put both rings on, putting the inner rings onto the shaft, while pulling the outer one from the hub. This puts pressure on an inside part of the hub and connects it to the shaft with the friction fit pressure connection. The resultant fit is able to withstand extreme forces and makes it a good option for light as well as heavy-duty applications.

Due to the evenly distributed compressive forces along the circumference of the shaft, the locking assemblies prevent misalignment and offer maximum performance with a sturdy and secure connection. Our locking assemblies are made using standard Allen screws that are tightened with standard tools. There is no additional assembly or machining is needed. In the case of disassembly, it is easy. Once the locking screw has been loose, the entire assembly will release automatically, and the shaft and hub can be moved for adjustment, removal, or replacement if required.

Locking Assembly for Sale

As a locking assembly manufacturer, we will do our best to serve you. If you need customized products, or the products you need are not found on our website, or need a product catalog, don't worry, more of our products are still being uploaded. You can email us directly, and we will reply to you within 24 hours!

Precision Roller Chain

Precision Roller Chain

Precision Roller Chain

STAINLESS STEEL CHAIN

STAINLESS STEEL CHAIN

STAINLESS STEEL CHAIN

SMR reducer

SMR reducer

JDLB reducer1

JDLB reducer

Fluid couplings

ROOTS VACUUM PUMPS

vacuum pumps

vacuum pump

T Type Flanges For Use With Taper-Lock Bushings

B Type Flanges For Use With Bushings

S-Flex Sleeve Styles

S-Flex Assortment

Elastomer Models

S-Flex Couplings Overview

H Variety,L Form,SW Style Couplings

RRS Sort Radially Removable Spacer Couplings,C Sort Couplings

LC Form,AL and SS Kind Couplings

Jaw Coupling Choice Approach

Jaw Elastomers Overview

Jaw Variety Couplings

Grid Conventional Coupling and Spacer Type Effectiveness / Dimensional Data

Grid Coupling Selection Method

Overview of Grid coupling

Coupling Grease

Flanged Sleeve Overview

RA and RAHS Variety Coupings Overall performance Data

FSLX Type,FSPCR Sort Functionality Data

FHDFS Form,FMM Kind Performance Data

FHD Sort ,FHDFR Sort Flex-Rigid Couplings

FFR Form,FFS Floating Shaft Gear Coupling

Sier-Bath Steady Sleeve and Flanged Sleeve Couplings

FARR Coupling

Selection Procedure for DIR, DIRA, DILR, and DILRA Disc Couplings

DI-6,DI-8 Form Drop-In Center Industrial Coupling

SXC-6,SXCS-6,SXCST-6Type Closed Coupled Industrial Coupling

SU-6,SX-6,SX-8 Variety Industrial Coupling

Proposed Info Wanted to Specify a Disc Coupling

Methods In Deciding on A Disc Coupling

Disc Coupling Overview

Disc coupling

JDLB Make alternative

JDLB Series substantial precision worm gear units

Belt Installation And Reducer Application

SMR Gearbox Set up

SMR gearbox ordering instructions

SMR Gearbox Selection

SMR Reducer Specification

REVESIBLE FOR Energy UNITS

Electrical power UNITS FOR LIFT TABLE

Power UNITS FOR DOCK LEVELER

PALLET TRUCK Power UNITS

Material Managing Energy UNIT

SNOW PLOW Electrical power UNIT

DUMP TRAILER Power UNIT

Energy UNITS FOR DOUBLE-SCISSORS LIFT

Conveyor Chain Assortment

Leaf Chain - Standard Data and Variety

Servicing Free of charge Roller Chain - Common Info

Stainless Steel Roller Chain - Common Details

Corrosion and Temperature Resistant Roller Chain

ASME/ANSI Transmission Series Double Pitch Roller Chain

The Drive Chain Variety Method

Necessary Information and facts For Drive Chain Variety

ASME/ANSI Drive Chain

DK Detachable Teeth Sprockets

Technical Data --Chain Variety

Working with Chain Below Various Temperature

Technical Information Chain Selection

3D Bending Conveyor Chain

Sewage Treatment method Chain (WS or WAS Variety Chain)

Water Therapy Conveyer Chain

Block Chain

Bucket Elevator Chains

Conveyor Chain Exclusive for Precise Conveyance

DK Conveyor Chains Common Conveyor Chain

Variation of DK Common Conveyor Chain

Tiny Conveyor Chains Technical Details

Building and Elements of DK Conveyor Chains

Tiny Conveyor Chains

Free of charge Movement Chains and various Conveyor Chains

Double pitch chain

Regular Attachments

Conventional Conveyor Chain with Attachments Series (Single Pitch)

Fracture patterns of respective chain parts

Lubrication

Maintenance

The way to connect O-ring Chains Remarks to connect standard O-ring Chains

Installation

Layout of chain position

Chain Length and Sprocket Center Distance

Chain Assortment by Temperature

Ways to Select the appropriate Chain

Dimensions of Sprocket

Chain Wear-elongation Check Gage

C-Top (Chain Cover)

Roller Chain Coupling

Leaf Chain

Silent Chain

Engine Mechanism Chain

Tiny Pitch Chain

Roller Chains for Power Transmission Specialty Chain Series

Roller Chains for Electrical power Transmission Minimal Noise Chain Series

Low-Temperature Resistant Chain (TK)

Stainless Steel X-Ring Chain

Stainless Steel Chain (SS/SSK)

Double Guard Chain (WG)

Hi-Guard Chain (E)

Nickel Plated Chain (N)

Sintered Bushing Roller Chain (UR/ URN)

O-Ring Chain (LD)/X-Ring Chain (LX)

DH-α Chain

Strong Bushing Chain (HT/D), (D)

HI-PWR-SHK Variety Roller Chains

HK form roller chains

High power roller chains

Worldwide standard chains complying with JIS and ANSI

Development and Parts of Chain

SHARP Top CHAINS

Pipeline centrifugal pump&slow rotary velocity centrifugal pump

GW Type No-jam dredge pump

Style “MD” ELEVATOR BUCKETS for general goal elevators

ELEVATOR BUCKETS

700 CLASS PINTLE CHAIN

400 CLASS PINTLE CHAIN

TRANSFER CHAIN

“H” CLASS MILL CHAIN

Mixture CHAIN

RIVETLESS DROP FORGED CHAIN BAR LOOP CHAIN

MXS CLASS STEEL DRIVE CHAIN

MSR CLASS BUSHED ROLLER STEEL CHAIN

SS CLASS BUSHED STEEL CHAIN

PRECISION ROLLER CHAIN

Vacuum Pumps

Vacuum Pumps

ROTARY PISTON VACUUM PUMPS

Root Vacuum Pumps

VACUUM PUMPS OF SPIRAL SLICE Sort

Y YD YS Series three-Phase asynchronous Motors

Y YD YS Series three-Phase asynchronous Motors

YC YL SERIES MOTORS

Y2 Series three-Phase asynchronous Motors

worm drive servo

AUGER DRIVE EARTH DRILL ATTACHMENT

agricultural gearbox

China fluid coupling

China fluid coupling

fluid coupling

rotary cutter gearbox

Bush chain

Slewing bearing

Servo coupling

Sheave pulley

Flat pulley

Conveyor sprocket

Double sprocket

Hydraulic motor

Bike sprocket

Cast chain

Mechanical chain

Conveyor chain

Silent chain

Conveyor chain

Cycloidal gearbox

Planetary gear motor

Irrigation gearbox

Servo gearbox

Sugar mill gearbox

Hypoid gearbox

Piston air compressor

Greenhouse gearbox

Right angle gearbox

Speed gearbox

Idler sprockets

Drive shaft

PTO gearbox

Timing belt pulley

Air compressor

Bevel gear

Spiral Bevel Gear

Synchronous Pulley

Agricultural chains

Drive chain

Electirc motor

Screw Jack

Helical gearbox

Worm speed reducer

Planetary gearbox

Fluid coupling

Agricultural gearbox

Hydraulic motor

Worm redction

Motorcycle sprocket

Roller chain sprocket

Roller chain coupling

Rope pulley

Piston air compressor

Aluminum sprockets

PTO Belt Pulley

PTO Belt Pulley

Taper lock pulleys

Engine Sprocket

Jaw Coupling

Car pulley belt

Aluminum collar

Motorcycle sprocket

Metric Sprockets

Toothed pulley

Adjustable pulley

Transmission sprocket

Vacuum pump

Taper pulley

Toothed belt pulley

agricultural gearboxes

agricultural gearbox

Spring pulley

Heavy duty pulley

planetary gear unit

planetary reducer gearbox

GEAR COUPLING

Agricultural chain

GEAR COUPLING

GEAR COUPLING

China fluid coupling

China fluid coupling

China fluid coupling

planetary track drive

Greenhouse geared motor

Plastic pulley

planetary wheel drive

precision planetary gearbox

PINTLE CHAIN 442 445 452 etc....

rotary cutter gearbox

Sprocket wheel

inline planetary gear reducer

epicyclic gearbox

Steel sprocket

Conveyor chain sprocket

zero backlash planetary gearbox

zero backlash gearbox

Cast pulley

Taper pulley

planetary gear reduction

worm drive servo

Weld On Hubs

Planetary Drive

planetary gear system

planetary gear motor

variable speed gear motor

Timing idler pulley

planetary gear reducer

Timing tensioner

Tensioner Pulley

Idler pulley

double reduction worm gearbox

compact worm gearbox

Gearbox Worm Drive

aluminium worm gearbox

Tensioner wheel for Auto parts

udl speed variator

Idler wheel for Auto Parts

self locking gearbox

helical worm gear motor

Tractor Pto Shaft

nema gearbox

stainless steel worm reducers

Tractor Pto Drive Shaft

small worm gearbox

worm wheel gearbox

Metal pulley

right angle worm gearbox

Mechanical Coupling

worm reduction gearbox

worm gear box assembly

Driven sprocket

worm wheel gearbox

worm wheel gearbox

Torque Arm

worm gear motor

Stainless steel sprocket

worm motor

worm gear speed reducer

worm gear reduer

Aluminum sprockets

plastic roller chain sprockets

Timing Belt

worm reduction

Idler sprockets

worm gear motor

worm reduction

worm drive shaft

Helical Gearbox

Cycloidal gearbox

Tapered Roller Bearing

Planetary Gearbox

taper bore bushing

Taper Adapter

Super Power Lock

Engine Sprocket

Steel Collar

Steel Ball Bearings

spiral bevel gearbox

Stainless Steel Gear Rack

gearbox for agricultural machinery

helical spiral bevel gear motor

Split Taper Bushing

Double Pitch Chain Sprockets

spiral bevel helical gearbox

low backlash gearbox

Split Collar

low backlash planetary gearbox

Slewing Bearing

low backlash worm reducer

low backlash worm drive

Shaft Clamp

worm drive servo

gearbox for agricultural machinery

Roller chain sprocket

servo planetary gearbox

zero backlash planetary gearbox

zero backlash gearbox

servo gearbox

Scroll Air Compressor

Double sprocket

servo motor gearbox

screw jack

servo gear reducer

Screw Air Compressor

servo motor gear reducers

precision gearbox

construction and working of constant mesh gearbox

servo gearhead

servo motor and gearbox

servo reducer

servo worm reducer

roll-up units for greenhouse

planetary gearbox for servo motor

Taper lock pulleys

irrigation gearbox

rear drive shaft

Center-drive gear motor

center pivot gearbox

rack pinion steering

center gearbox

gearbox construction

Final wheel drive

crane duty helical gearbox

Driveline gearboxes

Driveline Motors

greenhouse gear motor

greenhouse gearbox

Metric Sprockets

rack pinion

greenhouse gear reducer

rack drive for greenhouse

greenhouse reducer

rack and pinion steering

gearbox for greenhouse

rack and pinion

Gear Motor For Greenhouse

Industrial sprocket

Greenhouse Roll Up Side Motor

automatic roll up sides greenhouse

qd bushing

Manual Roll Up For Greenhouse

Synchronous Pulley

Pto Spline Shaft

greenhouse electric roll up motor

greenhouse curtain motor

Greenhouse Auto Vent

greenhouse exhaust fan

greenhouse vent fan

automatic greenhouse vent

Greenhouse Vent Opener

greenhouse roll up motor for ventilation

Motor gearboxes for greenhouse

Agricultural Chain

PTO Driveline

rack drive for greenhouse

PTO drive shaft

roll-up units for greenhouse

Pto Adapter

udl speed variator

Variable Speed Drive

variator motor

variable speed motor

variable speed electric motor

variable speed gear motor

variable drive motor

variable speed drive motor

Power Take Off Shaft

Toothed pulley

variable speed transmission

Power Lock

parallel helical gearbox

variator gearbox

plastic rack and pinion

variable speed gearbox

screw jack

worm gear screw jack

worm screw jack

Nylon Gear Rack

worm gear jack

Rope pulley

Timing belt pulleys

helical bevel gear reducer

gear rack for elevator

locking device

Automatic Window Opening System gear rack

bevel helical gearbox

Gear Rack For Window Opener

locking collar

helical gear reducer

Lock Assembly

Gear Rack For Rack Actuator

Liquid-Ring Vacuum Pump

gear rack for railway axle

gear rack for automobile

cyclo motor

gear rack for Greenhouse

Taper lock pulleys

automatic door rack

gear rack for Door opener

linear gearrack

cycloidal gearbox

gear rack for Construction machinery

Electric motor pulleys

Rope pulley

gear rack for Material Handling Industry

gear rack for Machine Tool Industry

Electric motor pulleys

gear rack for Woodworking Industry

gear rack for Aerospace Industry

gear rack for Machine Tool Industry

gear rack for Aerospace Industry

plastic rack and pinion

Flexible Drive Shaft

Nylon Gear Rack

hydraulic planetary drive

Driveshaft Yoke

precision planetary gearbox

Flexible Gear Rack

Multipul pulley

Deep Groove Ball Bearing

linear gearrack

micro planetary gear motor

Stainless Steel Gear Rack

Clamping Shaft Collars

hydraulic planetary drive

spur gear rack

cast aluminium

sun planet gear

Ground Racks

Cardan Shaft

Ground Helical Gear Racks

Helical Gear Rack

plastic gear rack

metric gear rack

Custom pulley

rack pinion steering

rack and pinion steering

Spinning pulley

rack pinion

rack and pinion

Cardan Joint

Timing Belt

Bolt On Hubs

car pulley belt

multi stage planetary gearbox

taper lock bushing

aluminum collar

taper lock bush

bevel planetary gearbox

PTO Belt Pulley

PTO Belt Pulley

helical gear

qd bushing

taper bore bushing

geared motors

Weld On Hubs

Bolt On Hubs

Taper Adapter

Compound pulley

hollow shaft planetary gearbox

differential gear

beval gear

Split Taper Bushing

Small Electric Motor

Lock Assembly

Screw Air Compressor For Laser Cutting

Three Phase Motor

planetary reduction drive

three phase ac induction motor

Single-Phase Induction Motors

Single-Phase Induction Motors

Single-Phase Induction Motors

planetary reducer gearbox

Power Lock

Single Phase Electric Motor

locking device

Q&A about ac motors and induction motors

Super Power Lock

Hydraulic cylinder

PTO drive shaft

PTO Driveline

Adjustalbe pulley

Cardan Shaft

gear reducer

Power Take Off Shaft

Brushless Ac Motor

Planetary Slew Drive

Air Compressor For Hyperbaric Oxygen Chamber In Hospital

Air Compressor For Dairy Equipment

Ac Induction Motor

Ac Electric Motor

Tractor Pto Drive Shaft

3 Phase Electric Motor

Tractor Pto Shaft

Pto Spline Shaft

Cardan Joint

precision planetary gearbox

Flexible Drive Shaft

10 Hp Electric Motor

front drive shaft

epicyclic gearbox

Induction Motor

hydraulic winches

rear drive shaft

Hydraulic Pump

Hyd Cylinder

Electromotor

Cable Pulley

Electromagnetic Motor

Electrical Motors

electric fan motor

planetary gearhead

Electric Drive Motor

Air Compressor For Tire Production Equipment

Chain Sheave

Air Compressor For Production Of Chemical Raw Materials

Driveshaft Yoke

Air Compressor For Organic Fertilizer Production

Air Compressor For Medical Industry

planetary gear box

Chain Sheave

Air Compressor For Medical Apparatus And Instruments

planetary gear motor

Air Compressor For Laser Cutting

Air compressor for iron ore machinery

stainless pulley

Slewing Bearing

100 hp electric motor

Steel Ball Bearings

1 Hp Electric Motor

Winch pulley

double reduction gear reducer

1 Hp Electric Motor

Deep Groove Ball Bearing

Tension pulley

worm gear set

Tapered Roller Bearing

transmission chain

self locking gearbox

timing chain

cast aluminium

steel pintle chain

steel chains

Special Chains

silent chain

Torque Arm

Side Bow Chain

Timing Pulley

Ploy Steel Chain

leaf chain

Automobile Gears

hollow pin chain

Ratchets wheel

gear chain

Shaft Clamp

Forgin Detachable Chain

Drive sprocket

Chain sprocket

duplex chain

aluminum gear

Drag chain

double flex chain

Clamping Shaft Collars

plastic worm gear

detachable chain

Conveyor Chain for Mine Machinery

rotary cutter gearbox

chain mc33

Steel Collar

shaft coupling

PIN coupling

Cast Caterpillar Chain

Cast Caterpillar Chain

ca550 roller chain

ca550 roller chain

bush chain

locking collar

Flange Coupling

bicycle chain

asa roller chain

Helical Gear

Agricultural chain

Rigid coupling

worm wheel

worm gear components

spiral gear

multi start worm gear

miter gear

Internal Gears

metric worm gears

Differential Gear

Differential Gear

Gear Coupling

stainless collar

Flexible coupling

rotary cutter gearbox

greenhouse gearbox

rotary cutter gearbox

China fluid coupling

China fluid coupling

CC CLASS CRATE CONVEYOR CHAINS

China Professional Plastics OEM Accept Custom Plastic Injection Part ABS Injection Molded CHINAMFG Suppliers

China OEM Customized Injection Molded CHINAMFG with ABS, PA66, PE

China Good quality Customized Plastic Injection Molded Parts

China high quality OEM Service High Quality Molded Moulding Plastic Injection Silicone Rubber Part

China Best Sales OEM Accepted Precision Injection Moulding Process Plastic Precision Injection Molding Customized Molded CHINAMFG

China manufacturer OEM/ODM Customized Mould Manufacturer ABS/Nylon/PP/PC/Peek CHINAMFG Injection Molding for Small Molded Parts

China Good quality Custom POM ABS PP PA66 Clear PC Prototyping Plastic Injection Molded/Molding Parts

China Good quality ABS/PP/PS/POM/PE/PC/Nylon/TPE/PA66 CHINAMFG for Electric/Automotive/Auto/Electronic/Household Product by Injection Mould Molded Overmolding Insert Molding

China OEM Injection Plastic Molding Injection Molding Services China Plastic Injection Manufacture

Types of Locking Assemblies

Keyless Locking Assemblies

Keyless locking assemblies eliminate the need for keyways or keyslots. They consist of two main parts: an inner hub and an outer sleeve with matching tapered surfaces. By tightening screws or bolts, the outer sleeve is forced inward, creating a tight fit between the components.

Shrink Discs

Shrink discs utilize the principle of thermal expansion to create a secure connection. They consist of two halves with mating taper surfaces. When heated, the inner part expands, exerting radial pressure against the shaft and the outer part, effectively locking them together.

Interference Fit Locking Assemblies

Interference fit locking assemblies rely on a tight interference fit between the components. The locking assembly is designed with a slightly larger diameter than the bore of the hub or flange. During installation, the assembly is pressed or hammered into place, creating an interference fit and ensuring a secure connection.

Cam Locking Assemblies

Cam locking assemblies utilize a cam or wedge mechanism to create the locking action. As the cam is rotated, it generates axial forces that push the components together. This type of locking assembly is often used in applications where frequent disassembly and reassembly are required.

Threaded Locking Assemblies

Threaded locking assemblies, also known as thread-locking devices or threaded shaft collars, utilize threaded connections to secure components. They typically consist of a collar with internal threads and one or more set screws or threaded bolts. By tightening the screws or bolts, the collar grips the shaft, preventing axial movement. Threaded locking assemblies are simple and versatile, suitable for a wide range of applications.

These are just a few examples of locking assemblies available in the market. It's important to select the appropriate type of locking assembly based on factors such as the application requirements, torque transmission needs, ease of installation and removal, and environmental conditions. Consulting with manufacturers or engineering professionals can help determine the best locking assembly for a specific application.

Locking Assemblies Offer Several Advantages

Easy installation and removal

Many locking assemblies are designed for quick and simple installation and disassembly, allowing for efficient maintenance and replacement of components.

Backlash-free torque transmission

Locking assemblies provide a solid and rigid connection between components, minimizing or eliminating backlash and ensuring accurate torque transmission.

High torque capacity

Locking assemblies are capable of transmitting high torques, making them suitable for demanding applications.

Improved concentricity and alignment

Locking assemblies help maintain accurate alignment between shafts and rotating components, reducing vibration and wear.

Which Industries Use Locking Assembly?

As one of the leading locking assembly manufacturers, we can provide high-performance locking assembly equipment to companies in various industries.

Industries Served

Why Choose Us?

We are the most reliable in the industry when it comes to delivering highly engineered products that increase productivity and efficiency in industrial applications worldwide. A commitment to customer satisfaction and exceptional value permeates every business function.

Offers the lowest total cost of ownership

Highest quality products designed to help prevent equipment downtime and increase productivity and reliable operation

valuable expertise

The broad product offering is accompanied by a global sales specialist, customer service and maintenance support team, readily available.

Solutions that Improve Ease of Doing Business

A commitment to operational excellence ensures that the right

Products are in the right place at the right time.

Customer demand is our pursuit

Our customer commitment to your specific use case:

Outstanding expertise for optimal performance and reliability

best cost-benefit ratio

Short reaction times and high product availability